3D Printing Technology: Innovations and Impact

INTRODUCTION

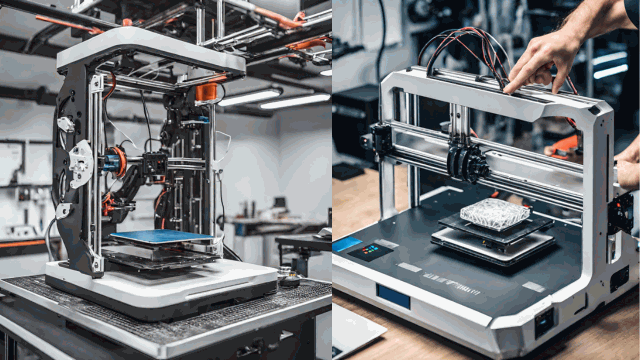

3D printing technology is a digital method that uses consecutive layers of material to build three-dimensional solid objects with finely sliced cross-sections. It is a more efficient approach than subtractive manufacturing, enabling complex shapes to be created with less material 3D Printing Innovations.

THE TECHNOLOGY OF 3D PRINTING

3D printing technology is classified into three categories:

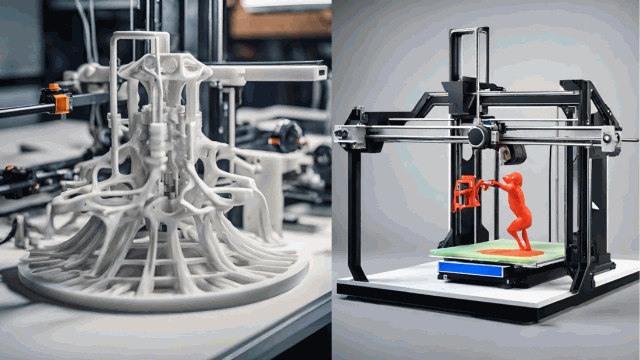

Sintering is a material-heating process that uses metal powder for direct metal laser sintering and thermoplastic powders for selective laser sintering to manufacture high-resolution products.

Melting

In 3D printing, materials are melted using technologies such as powder bed fusion, electron beam melting, and direct energy deposition with lasers, electric arcs, or electron beams.

Stereolithography is a photopolymerization method that uses light to selectively cure and solidify tiny layers of an object’s surface.

TYPES OF 3D PRINTING

Processes for 3D printing, also known as additive manufacturing, have been divided into seven categories:

JETTING OF BINDER

Binder jetting is a method that involves depositing a small layer of powdered material, such as metal, polymer sand, or ceramic, onto a build platform, followed by adhesive droplets.

Material extrusion, also known as fused deposition modeling (FDM), involves heating a filament spool and feeding it into an extrusion head, which softens and deposits the heated material at predefined spots, preparing the build platform for the next layer.

JETTING OF MATERIAL

Material jetting is a printing process similar to inkjet printing in which layers of liquid material are deposited from print heads, cured, and then repeated for the next layer.

Powder bed fusion (PBF) is a manufacturing technique in which heat energy, such as a laser or electron beam, selectively fuses regions of a powder bed to produce layers, which are then built upon to build a product.

SHEET LAMINATING

Laminated object manufacturing (LOM) and ultrasonic additive manufacturing (UAM) are two types of sheet lamination. For visual attractiveness, LOM employs alternate material layers and adhesive, but UAM employs ultrasonic welding for low-temperature, low-energy production of aluminum, stainless steel, and titanium.

VAT photopolymerization is a two-step process utilizing stereolithography (SLA) and digital light processing (DLP). For curing, SLA employs a single-point laser or UV source, whereas DLP flashes a single picture of each entire layer onto the vat surface.

ADVANTAGES AND DISADVANTAGES

The advantages of 3D printing include:

- Bespoke, cost-effective creation of complicated geometries: This technology enables the simple creation of bespoke geometric pieces with no additional complexity.

- Cheap start-up costs: Because no molds are required, the expenses connected with this manufacturing process are cheap. The cost of a section corresponds to how much material is utilized.

- Completely customizable: Because the method is based on computer-aided designs (CAD), any product changes are simple to implement without affecting manufacturing costs.

- Rapid prototyping: This procedure is perfect for rapid prototyping because the technology enables small quantities and in-house production.

- Allows for the development of parts with specified properties: While plastics and metals are the most commonly used materials in 3D printing, there is also the possibility of generating parts from precisely designed materials with desired properties.

The disadvantages of 3D printing include:

- While certain parts, similar to those made of metal, can have major areas of strength, numerous other 3D-printed parts can be more vulnerable than those delivered utilizing customary assembling techniques. These parts are frequently more brittle.

- High-volume cost increases: Large production runs are more expensive with 3D printing since economies of scale do not apply to this process as they do to other traditional technologies.

- Accuracy limitations: The accuracy of a printed part is determined by the machine and/or method utilized.

- Requirements for post-processing: The heft of 3D-printed objects need post-handling This could be sanding or smoothing to achieve the desired finish.

3D PRINTING INDUSTRIES

A variety of sectors, including the following, can benefit from 3D printing because of its versatility:

THE AEROSPACE

In the aerospace and aerospace industries, 3D printing is used to create light, geometrically difficult parts like blisks, minimizing lead times and material waste by generating an item as one whole component.

The automotive industry has adopted 3D printing for weight and cost savings, rapid prototyping of novel parts, and overnight printing for testing before bigger manufacturing runs, allowing for small-scale manufacturing.

HEALTH CARE

3D printing is being used in the medical field to create custom implants and gadgets.

Because of the speed of manufacture, creative freedom, and ease of design customization, 3D printing is ideal for the robotics business. This includes efforts to develop customized exoskeletons and nimble robots with increased agility and efficiency.

FAQs

What materials are suitable for 3D printing?

3D printing materials incorporate thermoplastics like acrylonitrile butadiene styrene (ABS), metals (counting powders), tars, and ceramics.

What amount of time does it require to print a 3D object?

Part size, printing settings, and finished part quality all influence printing time in 3D printing. Items of higher quality take longer to make. The method can take anywhere from a couple of moments to a few hours or days, contingent upon the speed, goal, and volume of material utilized.

While 3D printing has made huge advances, it actually misses the mark concerning contending with other assembling methods for high-volume creation. Injection molding, for example, allows for significantly faster mass production of parts.

Where will 3D printing go from now on?

The advancement of 3D printing technology may democratize manufacturing by allowing for larger-scale production projects and reduced costs, allowing its use to expand beyond industrial settings to homes, schools, and other places.

Toxic filament emissions from melting plastic filaments offer a health danger in 3D printing fumes, although adequate ventilation and extractor use can alleviate this issue.

Are there any future turns of events, like 4D and 5D printing, past 3D printing?

4D and 5D printing are examples of additive manufacturing breakthroughs. 4D printing lengthens the process by allowing items to self-assemble or change shape in response to environmental factors.

Using accurate multi-axis machines, 5D printing focuses on optimizing material utilization and producing structures with greater strength and reduced weight. Both methods contribute to advances in additive manufacturing technology.

You can either make a 3D model without any preparation or get one from a 3D library. There are several software tools available, including industrial-quality and open-source applications. Tinker cad is a good choice for novices because it is free and operates in a browser. It provides introductory lessons and exports the model as a printed file.

The model is then prepared for 3D printing by slicing, which is the process of breaking it into layers using software. The model is then printed layer by layer after being given to the printer by USB, SD, or Wi-Fi.

What are the costs of 3D printers?

The cost of a 3D printer shifts depending on its size, forte, and expected utilization. The most affordable 3D printers for beginning enthusiasts typically range from $100 to $500. Additional confusing models could cost somewhere in the range of $300 to $5,000. The cost of an industrial 3D printer can reach $100,000.

Get access all prompts: https://bitly.com/xyz